The Glue Talk Blog

Plastic straws are having a considerable impact on the environment. It is ironic that such a small actor is central to the movement against plastics. Plastic is now being replaced by other enhanced materials, and manufacturers are rising to the challenge of meeting demand for robust paper straws with sustainable credentials.

In Europe, there is an estimated 14.8 million tons of plastic waste generated every year. That causes concern as to how the packaging industry is perceived and demonstrates that more sustainable materials need to be readily available to customers.Plastic drinking straws are one of the culprits, and governments are acting. In the European Union, 27 countries will ban single-use plastic straws in June 2021. As we entered 2021, China banned single-use plastic straws, and in Canada, a ban that started as a campaign promise in 2019 will come into effect sometime in 2021. Taiwan has banned plastic straws, extending the ban to all restaurants this year with a prohibition on single-use utensils. In the U.S., Vermont and Maine banned single-use plastic straws in 2019 and 2020, respectively, and several U.S. cities also have bans.

As regulators legislate to force the reduction of single-use plastics, plastic straws are being replaced. While substitutes for the plastic straw have grown to include such materials as stainless steel, glass, dried grass or plant stems, bamboo, pasta, PHA, PLA, other new “biodegradable” plastics, the return to paper is a natural solution for manufacturers.

New level manufacturing efficiency with paper straws

Expectations are very high. H.B. Fuller has advanced the development of paper straws for very fast-moving paper straw machines. Manufacturing paper straws is a very different process to plastic: there are typically three plies of paper bonded together by a small amount of water-based adhesive using a core-winding machine.Taking this process to a new level now demands that we help businesses choose the right paper and adhesive to achieve the desired product performance – after all, no one wants a soggy straw! For that outcome, our global team of scientists and engineers provide on-demand technical support to guide our customers on how to efficiently produce durable liquid resistant straws at the lowest manufacturing cost possible and to profitably meet growing market demand.

A world-leading paper straw adhesive

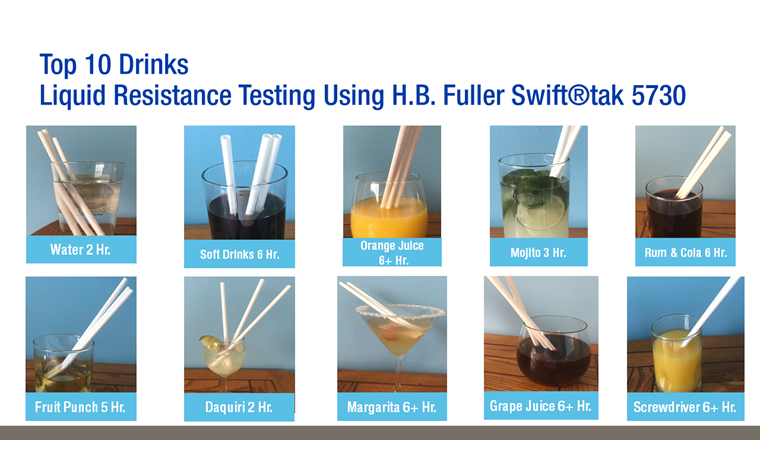

Swift®tak 5730 is at the forefront of innovation and is a world-leading paper straw adhesive. It is plasticizer-free, food safe, and has more than three-hour liquid resistance. Since it is suitable for corewinding and slot nozzle paper straw construction, Swift®tak 5730 has many features that make it a differentiated and efficient adhesive solution.

One of the unique points is that, unlike competitors, Swift®tak 5730 is a consistent clean machining adhesive that requires no filtration, reduces downtime and improves paper straw manufacturer productivity. This allows you to produce more straws per shift and lower your cost per straw. It also has multipurpose capability. In addition, it is validated on different paper substrates, and it can be used on a wide range of equipment with roller and slot nozzle applications at speeds higher than 100 m/min, such as Pakea, Eberle, ITM Tembo, Hauni and other equipment.

Since it is a water-based adhesive, it offers the water-resistant performance required by paper straws and the food-safe confidence demanded by consumers. And, not to forget your product price point – it is fast on the line and runs cleanly to maximize process efficiencies with consistent machining, provide faster uptime compared to competitors, and minimize machine downtime and the expense of replacement parts.

Swift®tak 5730 is higher in viscosity than competitor products and, therefore, less water is removed for drying – allowing for more efficient production. It also is suitable for bendy and straight straws, which allows you to consolidate adhesive SKUs.

Finally, this adhesive also excels in cutting down on manufacturing and maintenance costs and challenges. It’s quite invisible – a fast-setting product that is easier and cleaner to work with, and causes less wear on machinery than other paper straw adhesives.

The industry is steadily moving towards more eco-friendly processes and materials. Adhesives, the small, yet central, actor in the change towards circularity and sustainability are now helping manufacturers address major concerns with plastic.

Enable your manufacturing process with H.B. Fuller’s adhesive expertise and make your mark on building a better and more sustainable future. Contact us today.

Blog Categories

Blog Categories

Archive

- 2024

- 2023

- 2022

-

2021

- January (3)

-

February (7)

- Celebrating Exceptional Service During COVID-19 Complications

- Cyanoacrylates: What They Are and What They Do

- Innovative two-shot bookbinding adhesive

- Make a Difference 2020

- Problem Solving: Paper Straws in Drinking Beverages

- Stronger straws sustainable future

- Substances of Interest in Disposable Absorbent Hygiene Products

- March (4)

- April (4)

- May (4)

- June (5)

- July (2)

- August (5)

- September (2)

- October (1)

- November (3)

- December (2)

-

2020

- January (4)

- February (2)

- March (3)

- April (4)

- May (3)

-

June (7)

- Community Support in the Era of Coronavirus

- HBFuller Employee Creates Face Shields with 3D Printer

- Improved Packaging Integrity and Greater Customer Satisfaction

- Liquid-Resistant Paper Straws

- What is a Sealant?

- What Is the Future of Commercial Disinfectants?

- Winning over consumers with e-commerce packaging solutions

-

July (6)

- Employees Take Action to be Part of Healing and Growth

- Gain a competitive advantage with packaging adhesive solutions

- HB Fuller Company Foundations Commitment to Communities

- Packaging Solutions for the South African Agriculture Market

- Supporting Organizations That Provide STEM Education for Youth

- Where Does Sustainability Stand Amid COVID-19

- August (3)

- September (2)

- October (4)

- November (2)

- December (4)