Mass Balance

Consumers are demanding concrete actions and legislation to limit climate change. Since the announcement of the “European Green Deal” in 2019, this topic has gained strong momentum in the adhesive industry. Sustainable transformation is not a standalone challenge of single players but requires the commitment of the whole ecosystem. As an adhesive business, we rely mainly on fossil-based chemicals as an ingredient in many of our products. We therefore identified ISCC Plus certified isocyanate to formulate reactive hotmelt adhesive, enabling H.B. Fuller to partly replace fossil fuel-based raw materials by applying the mass balance approach.

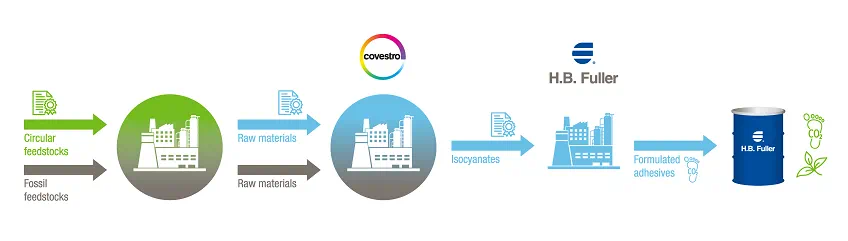

Explaining the Mass Balance approach

This new ingredient is a bio-attributed raw material accountable via a mass balance approach and will replace a proportion of fossil-based raw materials. Renewable raw materials are used as feedstock at the very beginning of the value chain and processed together with fossil-based ingredients in the same production units. The characteristic of the renewable feedstock process is then attributed to the end-product.

This approach assures that our customers’ processes will not be compromised in any way. The adhesive can be treated and processed in the same way as the product it replaces. And this process can reduce CO2 emissions and replace the extraction of finite resources with renewable raw materials.