View Related Pages

Bath Tissue and Paper Towel

Bath Tissue and Paper Towel

H.B. Fuller offers adhesive solutions for the tissue and towel industry, providing enhanced performance, improved mileage, and better bond strengths. Our products serve various applications, including corewinding and lamination.

View More

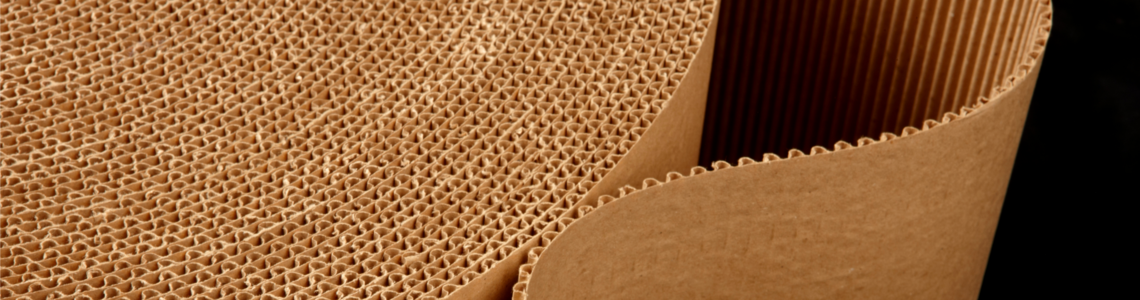

Corrugated and Paper Laminating

Corrugated and Paper Laminating

Enhance your operations with H.B. Fuller’s expert team and advanced adhesive technologies for corrugated and paper lamination needs. Our proven solutions optimize performance for glued lap, honeycomb, bulk box laminating, and more.

Read More

Envelope

Envelope

Achieve faster speeds and improve production quality with our envelope gum solutions that ensure secure seals and clean machine operation, offering solutions for side seam, front seal gum, self seal front gum, and window patch gum.

Read More

Folding Cartons

Folding Cartons

Optimize your folding carton adhesive applications and achieve secure, high-quality bonds with our portfolio of water-based, synthetic emulsion adhesives. H.B. Fuller’s Swift®tak line ensures bond integrity at all speeds.

Read More

Graphic Arts and Bookbinding

Graphic Arts and Bookbinding

Increase the quality and efficiency of your end products while reducing costs with our trusted portfolio of bookbinding adhesives. With a range of lab- and field-tested EVA and water-based adhesives, H.B. Fuller has got you covered.

Learn More

Multiwall Bags and Sacks

Multiwall Bags and Sacks

Partner with H. B. Fuller and let us generate value for your business with our innovative multi-wall bag adhesives. We cover every step of bags, sacks, and multi-wall sacks assembly, including laminating, cross fixing, and seaming.

View More

Paper Cups

Paper Cups

H.B. Fuller offers sustainable adhesive and coating solutions for the paper cup industry. Our water-based barrier coatings enable cups to be recycled, while Advantra® hot melt provides superior bonding and thermal stability.

Read More

Paper Straws

Paper Straws

Consumers demand low-impact alternates to plastic packaging, particularly in straws. H.B. Fuller products, including Swift®tak, offer superior durability, three-hour liquid resistance, and compliance with food contact regulations.

Read More

Adhesives for Tape, Labels, and Graphics

Adhesives for Tape, Labels, and Graphics

H.B. Fuller provides a wide range of pressure-sensitive adhesives, including hot melts, acrylics, and rubber formulations for your adhesive coated film, tape, label, and graphic needs.

View Now