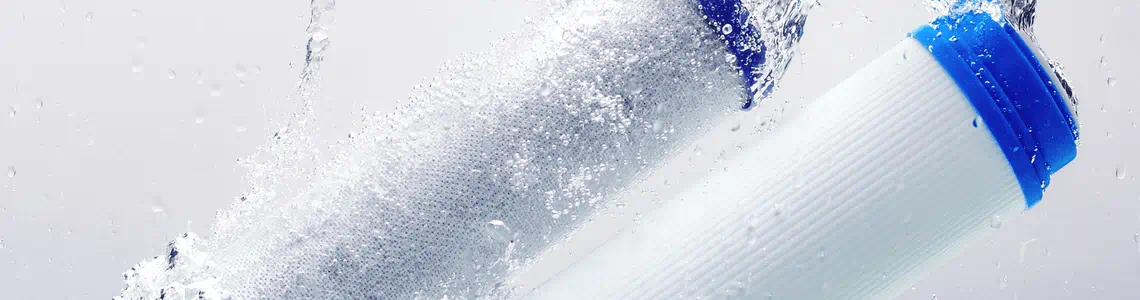

Membrane Separation

Liquid Separation and Water Filter Adhesives

Our membrane separation adhesives for RO membranes and hollow fiber filters are designed to help remove contamination and provide clean drinking water. These liquid filter adhesives are accompanied by a field proven longevity and safety performance record, and they are part of our global supply network.

We utilize our global manufacturing expertise to provide local service and filter know-how.

For a full list of all NSF-certified products from H.B. Fuller, click here.

Partner with us to address the challenges of automation, production optimization and reduction in cycle times with our liquid separation and water filter adhesive technologies and innovations.

Our liquid separation and water filter adhesives are for:

- Hollow Fiber Potting

- Spiral Wound Filters

Explore our comprehensive range of membrane separation solutions and applications, including technical documentation.

BROWSE PRODUCTS AND TDS