Introducing H.B. Fuller FullCheck™ For Packaging

Get Full Optics On Your End-Of-Line Packaging Data With FullCheck™ Data Analytics Consulting Services To Improve Your Quality, Productivity And Bottom Line!

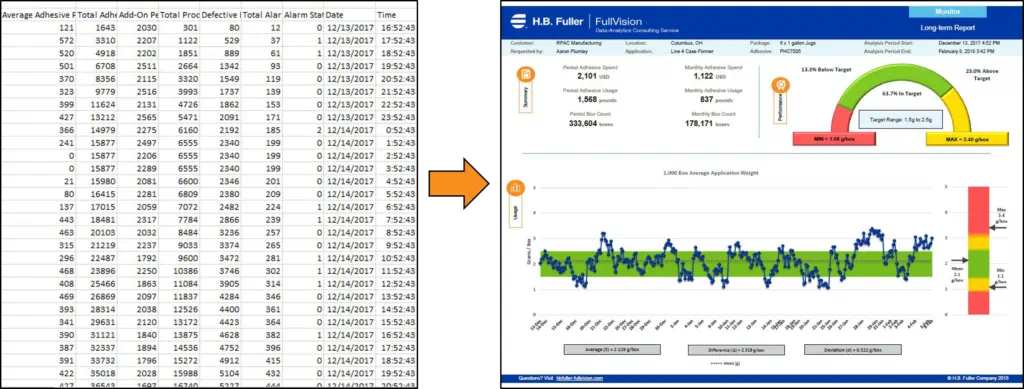

Introducing FullCheck™ Data Analytics Consulting Services to help you improve your end-of-line packaging applications. Big data is a challenge for many manufacturers, as they often find that there is not enough time and resources to collect, analyze and make sense of large quantities of data. H.B. Fuller experts use our proprietary software to analyze data collected from your Nordson® ProBlue Liberty ATS or ProBlue Melter retrofitted with ATS. From the analysis, we create at-a-glance data reports to help you track against industry benchmarks, mitigate operating costs and improve your product quality and line productivity. The complete FullVision Services include consultations with H.B. Fuller analysts who help you decipher the information in your reports. Our experts work to find improvement opportunities based on your data and make actionable, value-added recommendations on how to implement those improvements on your packaging lines.

Generate Reports

Make Improvements

- Standardize adhesive specifications

- Optimize adhesive usage

- Monitor performance vs. specifications

- Leverage the results to develop a focused training program

Reach Your Goals

- Realize material, time and energy savings *

- Improve quality control by monitoring and adjusting adhesive application

- Establish optimal specifications to increase productivity and accountability

- Achieve productivity goals and improve your bottom line