Technologies

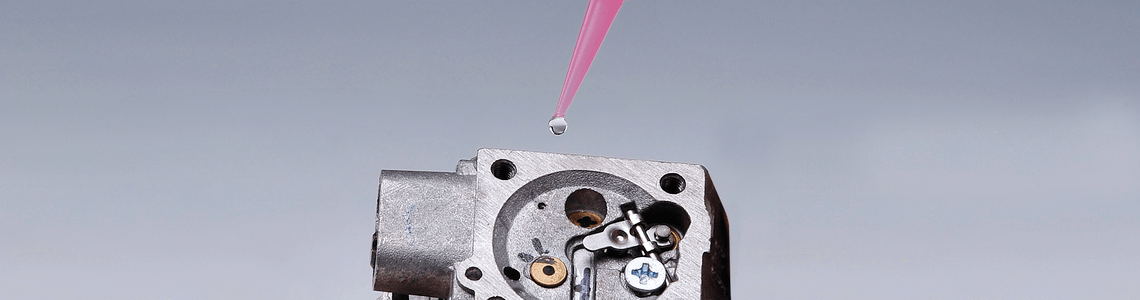

Introducing Our Adhesive Technologies

At H.B. Fuller, our team of industry-leading chemists and technicians is dedicated to providing you with an unparalleled range of adhesive technologies. We have a wide range of adhesives available, including hot melt, cyanoacrylate, water-based, urethane, epoxy, solvent-based, solventless, and tile-setting adhesives.

Our comprehensive product offering extends to mastics, coatings, and sealants, ensuring we are your one-stop destination for all your bonding needs. With a commitment to innovation and adherence to the highest industry standards, we are here to elevate your projects to new heights. Explore our adhesive technologies, and discover the difference in quality and performance that sets us apart.