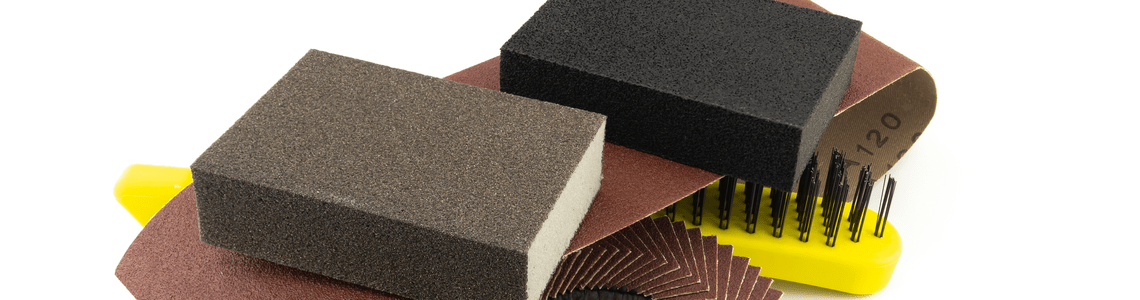

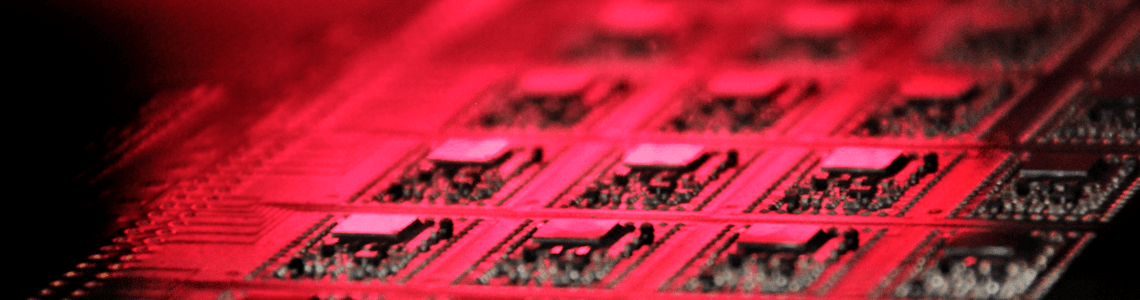

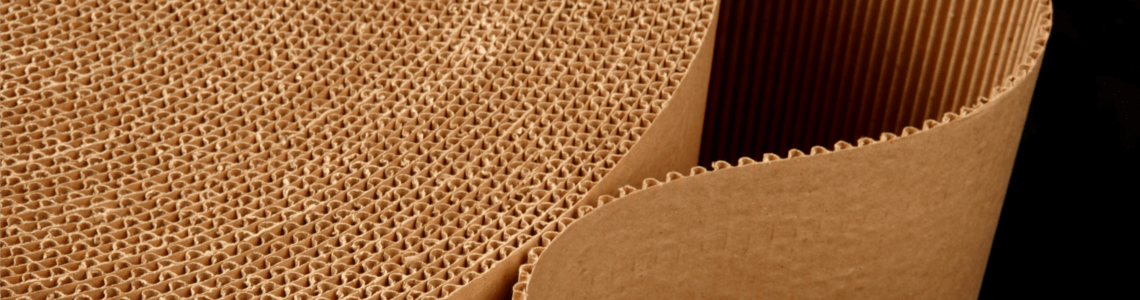

Applications

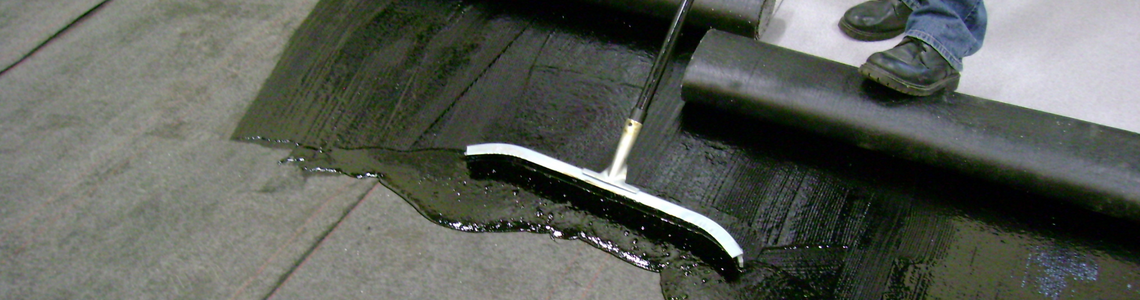

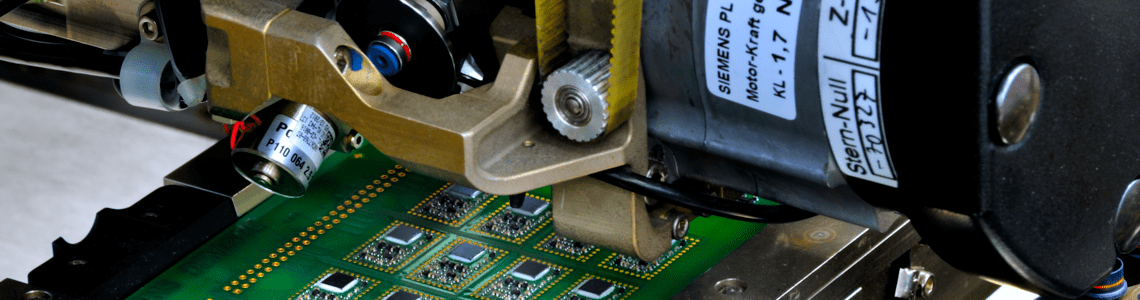

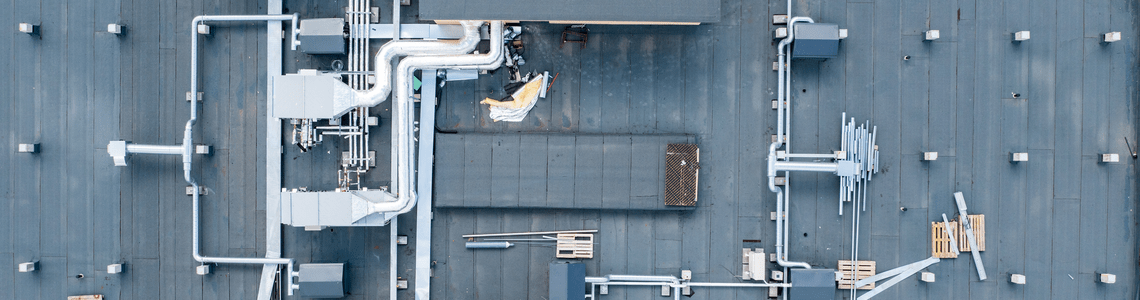

H.B. Fuller Adhesive Applications

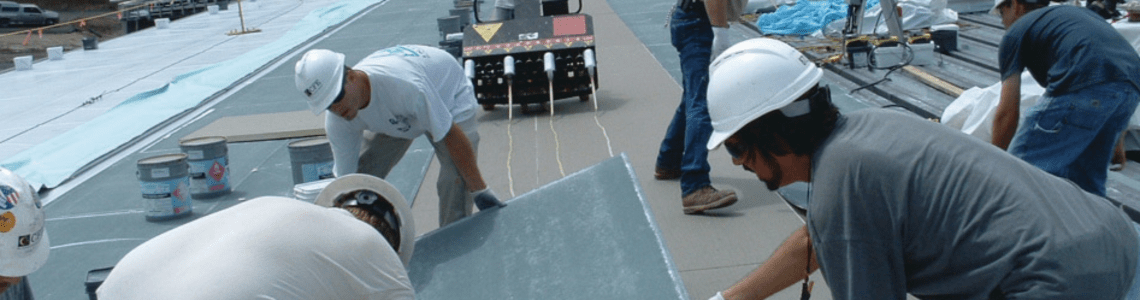

H.B. Fuller, a global leader in adhesives, offers an extensive and innovative range of adhesive products that meet your unique needs. Whether you're in packaging, electronics, construction, automotive, or any other sector, H.B. Fuller has an application to help you meet your business goals.

With a legacy of excellence and a pursuit of innovation, H.B. Fuller has become a trusted partner in adhesive technology. Our commitment to quality, sustainability, and customer satisfaction shines through adhesive formulations and products, enabling customers to embrace limitless possibilities in your applications.